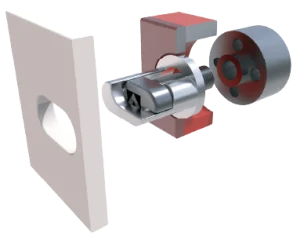

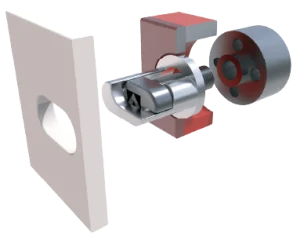

MAK-Lok™ Single Sided Bolting Systems

A Smarter Fastening Solution for Safer, Faster, and Stronger Wear

Makuri can supply a wide range of liner designs and mounting options to suit existing site skirting frames and can custom-design additional systems to suit individual requirements.

Makuri technology has chosen to specialise in this are as such we can address all these issues covering Design, Materials, Mounting and Monitoring and are all covered within the Makuri Intelligent Design™ process

Applying the correct internal skirting system allows us to guarantee a lower TCO and provide greater sustainability to our industry

We understand process plant front end maintenance and operational practices better than most. Contact us to see how we can optimise your process plant front end to improve overall plant throughput, maximise asset utilisation and lower carbon footprint

A Smarter Fastening Solution for Safer, Faster, and Stronger Wear

You cannot copy content of this page

Adding {{itemName}} to cart

Added {{itemName}} to cart