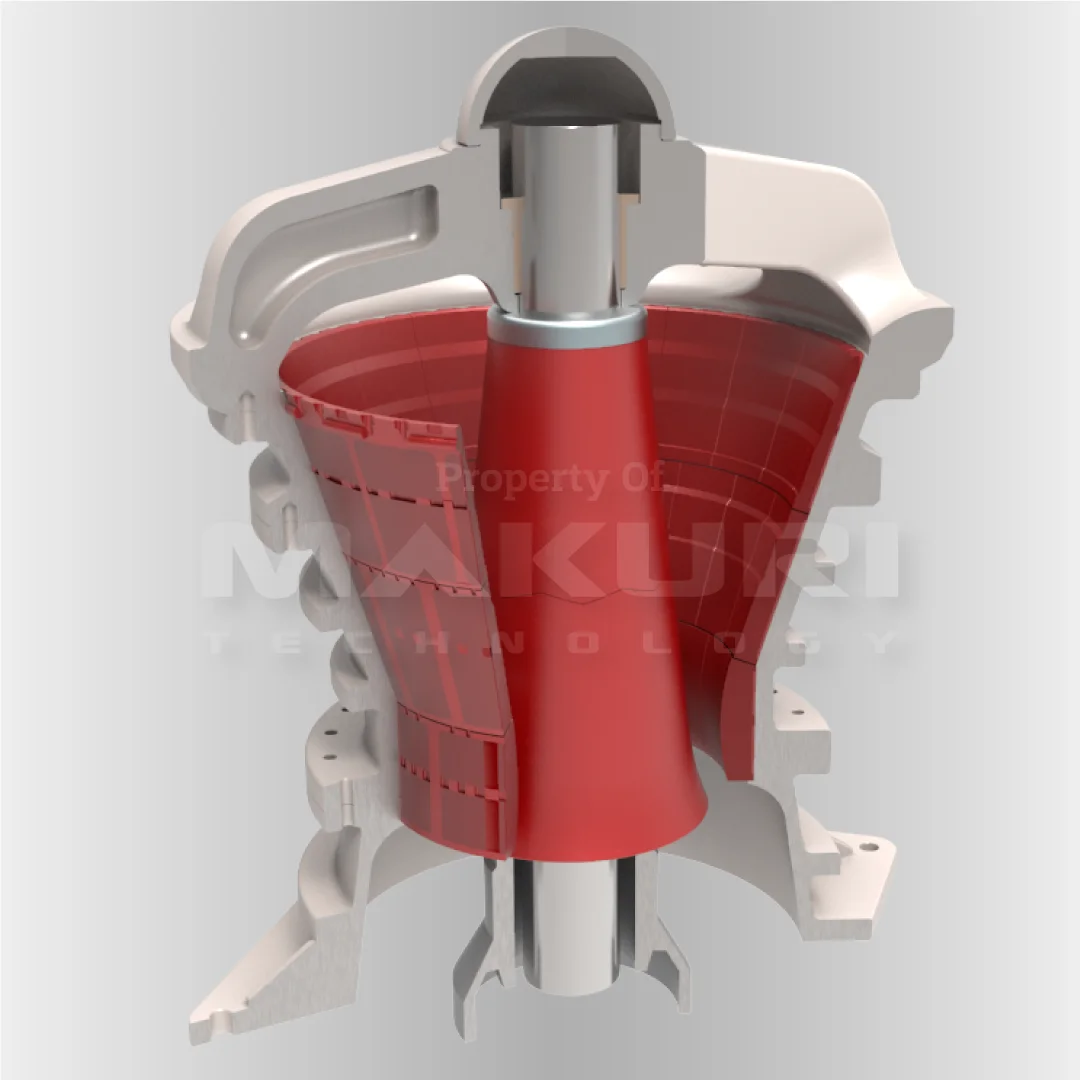

Gyratory Crushers are used for crushing ore in mining. Gyratory crushers are designed to handle large rocks and ores with high hardness and toughness.

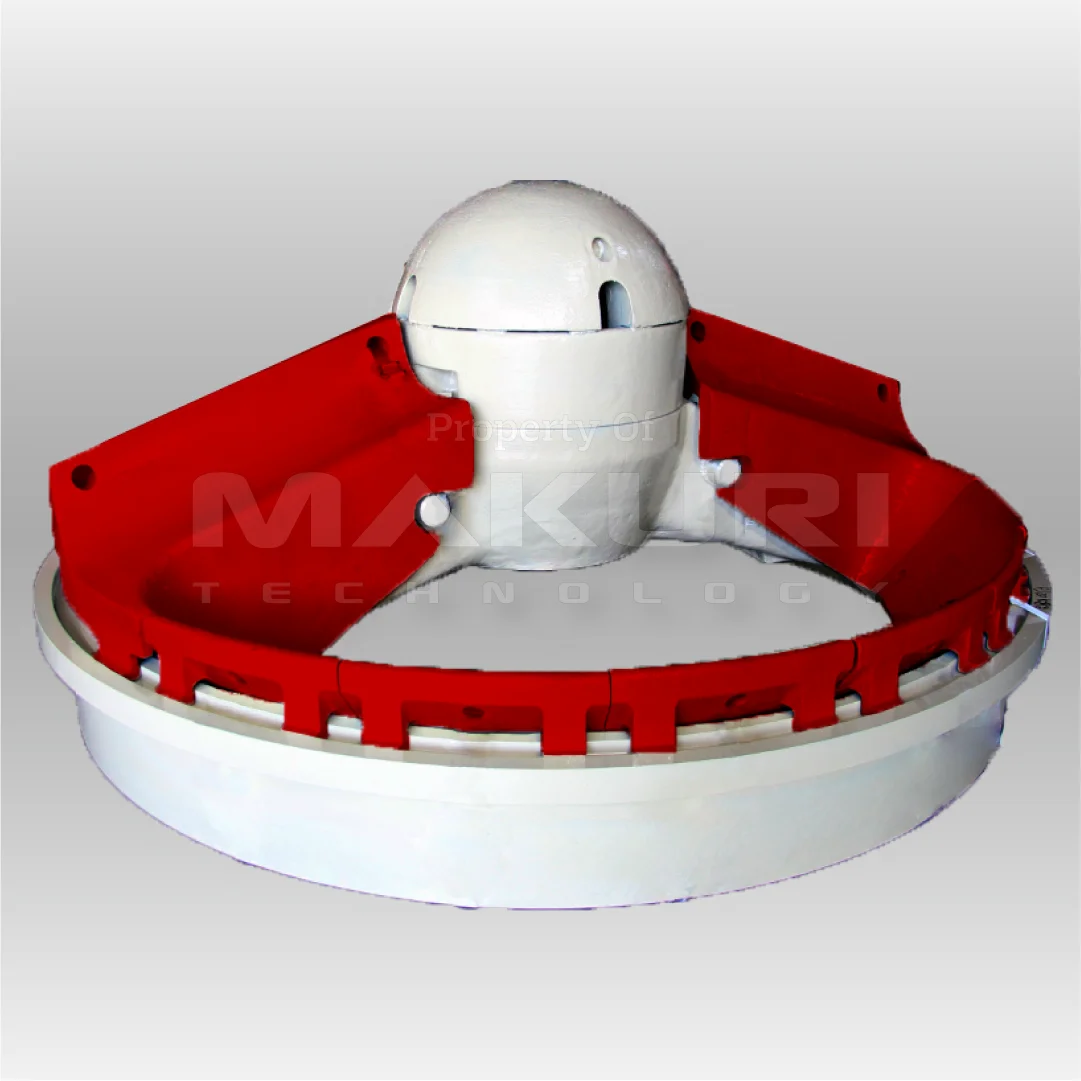

Proper design of both gyratory crusher mantle and concave liners leads to lower and more consistent crushed product size, better throughput, highly predictable liner changeout intervals and overall better asset utilisation.

Gyratory Crushers

Typical Problems

- Inconsistent crushed product size

- Poor and excessively large product shape blocking secondary crushers or SAG mill feed chutes

- Unpredictable tonnes throughput / operating hour

- Unpredictable stockpile product size distribution

- Unpredictable liner life and poor use of mantles to concave life ratio

- Poor or excessive power utilization

- Poor throughput and high-power draw in later mantle and concave life

- Excessive planned and unplanned maintenance

- High carbon footprint thru poor liner utilisation

Makuri Solutions

Longer life liners with better tpoh and psd

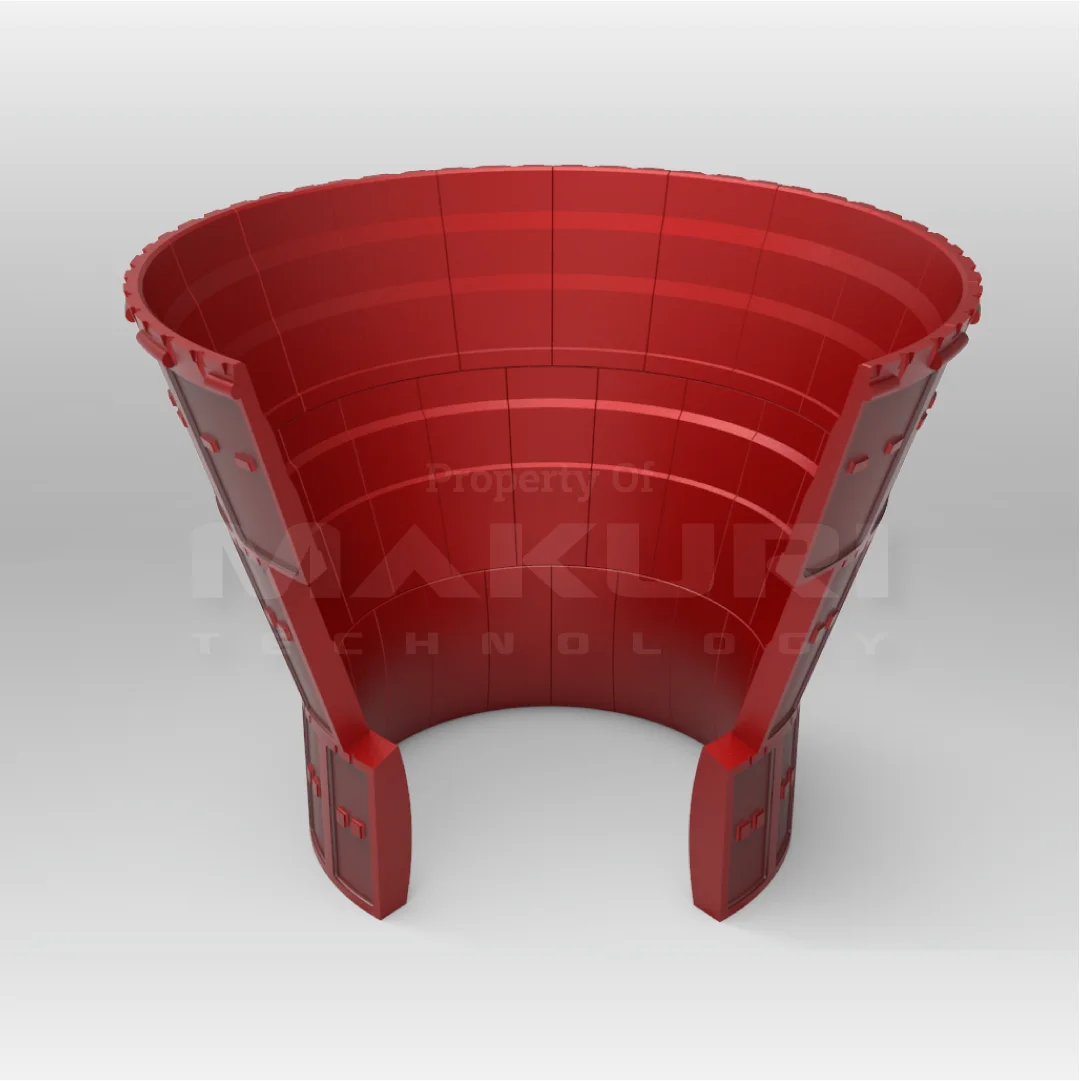

Using Makuri proprietary Intelligent Design™ processes, we are able to supply gyratory crusher liners that will often exceed OEM performance by more than 100%, while still providing consistent performance throughout the life of the liner set. Our superior cavity design capabilities coupled with high quality materials and extensive quality control ensure that our products perform as expected and in line with increased operational demands of better tonnes / operating hour (tpoh) and lower product size distribution (psd).

To achieve this, we use a combination of alloy steel, white iron and manganese concave liners with carefully designed smooth or corrugated mantle liners to provide an optimum solution for each individual site. Compatibility between mantles and concaves is crucial, as are tonnage requirements and liner life. These can all be optimised by Makuri, allowing us to guarantee a lower TCO and provide greater sustainability to our industry.

We understand crushing better than most. Contact us to see how we can optimise your primary gyratory crushing to improve overall plant throughput, maximise asset utilisation and lower carbon footprint.